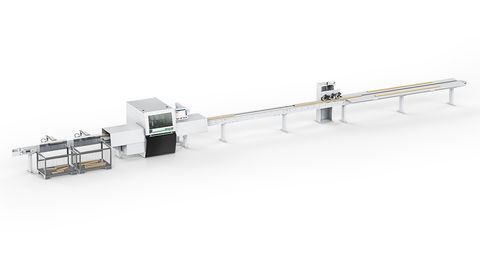

Optimizing cross-cut saw SOLID CUT TF 2000 Exact: The first choice for maximum accuracy

When it comes to maximum length accuracy, the SOLID CUT TF 2000 Exact is the best choice. With its special measuring method, it achieves length accuracy of up to ± 0.5 mm - for up to 8 preferred lengths. The accuracy of the SOLID CUT TF 2000 Exact does not, however, compromise its high daily capacity! Intelligent saw blade control can reduce tears and achieve cutting surfaces of the most superior quality. To achieve maximum squareness of the cut, active lateral pressure is also available, which additionally presses the workpiece against the stop guide. Maximum precision and, in many cases, the avoidance of an additional work step are the result.

Different requirements - different prices

The price of a WEINIG machine is just as individual as your requirements are. Therefore, let us discuss briefly what is most important to you – you will then receive our preliminary, non-binding quote.

Personal advice – for higher productivity and greater efficiency

Together with your WEINIG expert you will find the ideal machine for your requirements. Simply submit the completed form, and your local WEINIG expert will be happy to discuss all further details with you.

The WEINIG SOLID CUT TF 2000 Exact provides

- VarioSpeed infeed belt as standard

- 5 driven feed rollers from below, pressure rollers from above

- Servo-controlled saw stroke as standard

- Cutting of cross-sections up to 260 x 12 mm or 160 x 80 mm is possible

- Saw blade diameter 500 mm

- Integrated waste gate as standard

- Measuring wheel in front of saw blade

- Min. fixed length behind saw blade: 140 mm

- Cutting tolerance ± 0.5 mm for up to 8 preferred lengths of up to 2,500 mm

Technical Details

Increased profitability

Our optimizing cross-cut saws offer high performance potential in every respect. To maximize this potential, the intelligently controlled VarioSpeed, among other things, reduces the spacing between consecutive workpieces as much as possible. The SOLID CUT thus provides a continuous supply or workpieces, so that the idle time of the machine is minimized. This increases the efficiency and productivity of the optimizing cross-cut saw.

Reliability and safety as standard

Outstanding precision

Future-oriented and flexible

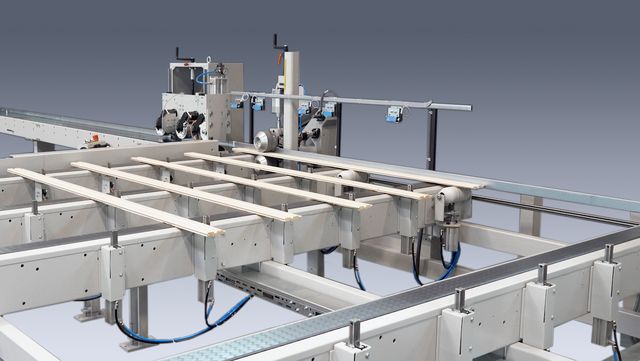

Secure workpiece guidance

Options for extension

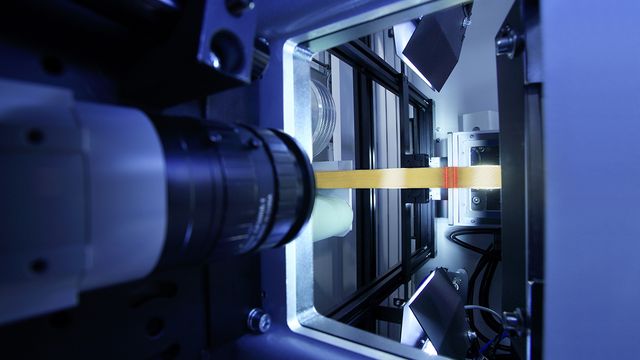

WEINIG scanner systems

Workpiece properties can be detected fully automatically and during production. Cutting is then performed automatically based on the data obtained.

Workpiece marking

Thanks to workpiece marking, part allocation can be significantly simplified. The marking can be adapted individually.

SOLID CUT PFtacker

When producing preferred lengths, the SOLID CUT PFtacker forms a neat stack, adding stack slats between the layers if desired.

Further information

Brochures

Simple, fast and sustainable: more details in a downloadable PDF document.

Download brochure